Material Hub > Materials

Materials

-

category aktorische Formgedächtnislegierungendensity –tensile strain at break –

-

category superelastische Formgedächtnislegierungendensity –tensile strain at break –

-

category superelastische Formgedächtnislegierungendensity –tensile strain at break –

-

category superelastische Formgedächtnislegierungendensity –tensile strain at break –

-

Geschlossenzelliger Aluminiumschaum (pulvermetallurgisches Verfahren)

Fraunhofer IWU, Abteilung Leichtbau, Textiltechnologien und Circular Economy

category zellularer Werkstoffdensity 0.7 g/cm³tensile strain at break – -

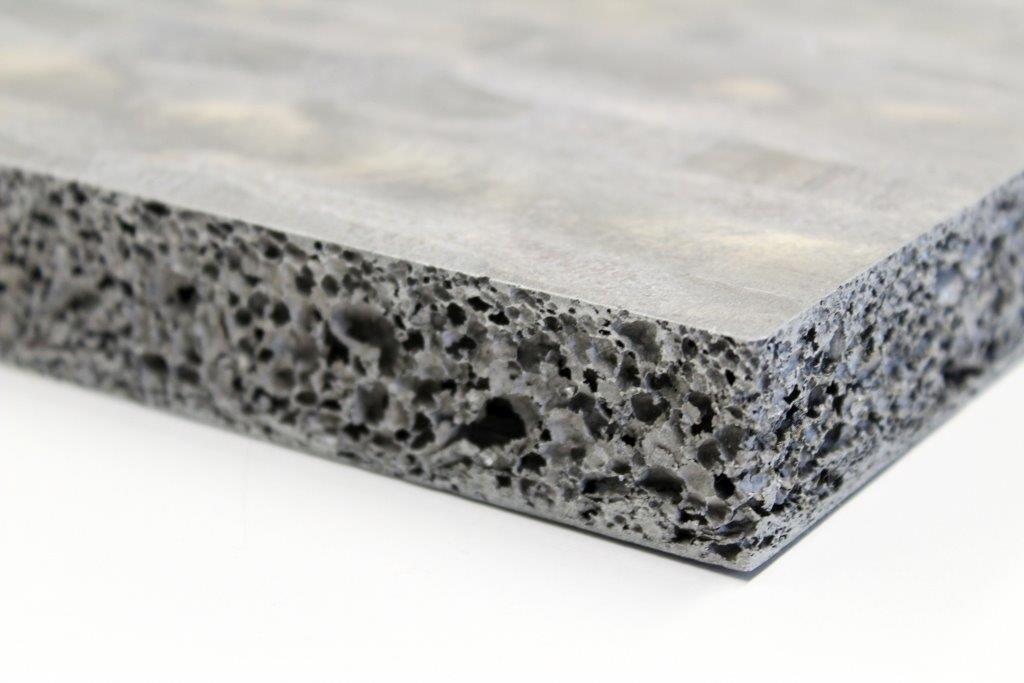

Sandwich mit Aluminiumdeckblechen und Aluminiumschaumkern (Aluminium-Aluminiumschaum-Sandwich)

Fraunhofer IWU, Abteilung Leichtbau, Textiltechnologien und Circular Economy

category Verbund mit zellularem Werkstoffdensity 0.7 g/cm³tensile strain at break – -

Sandwich mit Stahldeckblechen und Aluminiumschaumkern (Stahl-Aluminiumschaum-Sandwich)

Fraunhofer IWU, Abteilung Leichtbau, Textiltechnologien und Circular Economy

category Verbund mit zellularem Werkstoffdensity 0.7 g/cm³tensile strain at break – -

Offenzelliger Aluminiumschaum (Gießverfahren)

Fraunhofer IWU, Abteilung Leichtbau, Textiltechnologien und Circular Economy

category zellularer Werkstoffdensity –tensile strain at break – -

Offenzelliger Aluminiumschaum (schmelzmetallurgisches Verfahren)

Fraunhofer IWU, Abteilung Leichtbau, Textiltechnologien und Circular Economy

category zellularer Werkstoffdensity 0.16 g/cm³tensile strain at break – -

category elastomersdensity 1.22 g/cm³tensile strain at break > 110 %

-

category elastomersdensity 2.3 g/cm³tensile strain at break > 200 %

-

category thermoplasticsdensity 1.15 g/cm³tensile strain at break 120 %

-

category thermoplasticsdensity 1.32 g/cm³tensile strain at break > 50 %

-

category thermoplasticsdensity 1.4 g/cm³tensile strain at break 40 %

-

category thermoplasticsdensity 3 g/cm³tensile strain at break 280 %

-

category thermoplasticsdensity 2.1 g/cm³tensile strain at break 180 %

-

category thermoplasticsdensity 2.04 g/cm³tensile strain at break 250 %

-

category thermoplasticsdensity 2.25 g/cm³tensile strain at break 200 %

-

category thermoplasticsdensity 2.13 g/cm³tensile strain at break 140 %

-

category thermoplasticsdensity 2.17 g/cm³tensile strain at break 300 %

Facets

Application areas

producer

- Euroflex

- Fraunhofer IWU, Abteilung Leichtbau, Textiltechnologien und Circular Economy

- seal-mart GmbH

- Röchling Engineering Plastics SE & Co. KG 144

- Röchling Sustaplast SE & Co. KG 84

- Röchling Engineering Plastics 72

- Mitsubishi Chemical Advanced Materials 67

- Rhenotherm Kunststoffbeschichtungs GmbH 57

- Wefapress Beck + Co. GmbH 51

- show 21 more