Material Hub > Materials

Materials

-

category grey cast irondensity 7.3 g/cm³coefficient of linear thermal expansion –

-

category grey cast irondensity 7.3 g/cm³coefficient of linear thermal expansion –

-

category grey cast irondensity –coefficient of linear thermal expansion –

-

category grey cast irondensity –coefficient of linear thermal expansion –

-

category light metalsdensity 2.75 g/cm³coefficient of linear thermal expansion –

-

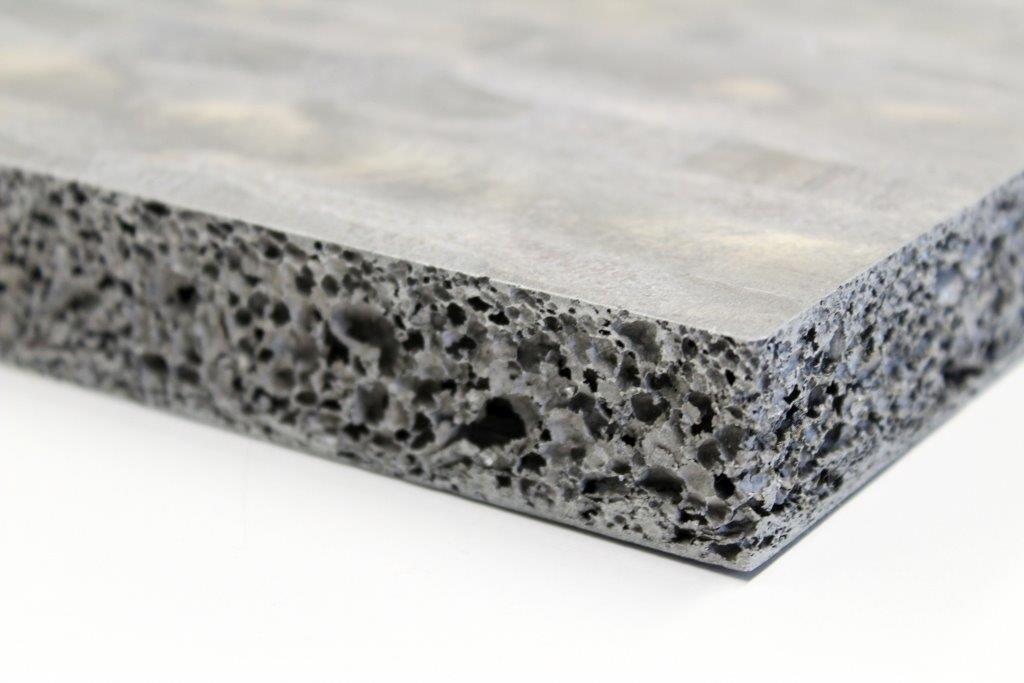

Geschlossenzelliger Aluminiumschaum (pulvermetallurgisches Verfahren)

Fraunhofer IWU, Abteilung Leichtbau, Textiltechnologien und Circular Economy

category zellularer Werkstoffdensity 0.7 g/cm³coefficient of linear thermal expansion 23.9 (10⁻⁶/K) -

Geschlossenzelliger Aluminiumschaum (schmelzmetallurgisches Verfahren)

Fraunhofer IWU, Abteilung Leichtbau, Textiltechnologien und Circular Economy

category zellularer Werkstoffdensity 0.25 g/cm³coefficient of linear thermal expansion 21 – 23 (10⁻⁶/K) -

Offenzelliger Aluminiumschaum (schmelzmetallurgisches Verfahren)

Fraunhofer IWU, Abteilung Leichtbau, Textiltechnologien und Circular Economy

category zellularer Werkstoffdensity 0.16 g/cm³coefficient of linear thermal expansion 22 – 24 (10⁻⁶/K) -

Rhenoguard® MK I-/AS Serie (Polyurethan und antibakteriell wirksame Additive)

Rhenotherm Kunststoffbeschichtungs GmbH

category Kunststoffbeschichtungdensity –coefficient of linear thermal expansion – -

category Schmierstoffe, Schmierfettedensity –coefficient of linear thermal expansion –

-

category plasticsdensity 1.41 g/cm³coefficient of linear thermal expansion 50 10⁻⁶/K

-

category plasticsdensity 1.39 g/cm³coefficient of linear thermal expansion 50 10⁻⁶/K

-

category plasticsdensity 1.38 g/cm³coefficient of linear thermal expansion 50 10⁻⁶/K

-

category plasticsdensity 1.31 g/cm³coefficient of linear thermal expansion 50 10⁻⁶/K

-

category plasticsdensity 1.36 g/cm³coefficient of linear thermal expansion 50 10⁻⁶/K

-

category plasticsdensity 1.31 g/cm³coefficient of linear thermal expansion 50 10⁻⁶/K

-

category plasticsdensity 0.95 g/cm³coefficient of linear thermal expansion 150 – 230 10⁻⁶/K

-

category plasticsdensity 0.95 g/cm³coefficient of linear thermal expansion 150 – 230 10⁻⁶/K

-

category plasticsdensity 0.95 g/cm³coefficient of linear thermal expansion 150 – 230 10⁻⁶/K

-

category plasticsdensity 0.95 g/cm³coefficient of linear thermal expansion 150 – 230 10⁻⁶/K