Material Hub > Materials

Materials

-

Geschlossenzelliger Aluminiumschaum (pulvermetallurgisches Verfahren)

Fraunhofer IWU, Abteilung Leichtbau, Textiltechnologien und Circular Economy

category zellularer Werkstofftensile strength –tensile strain at break – -

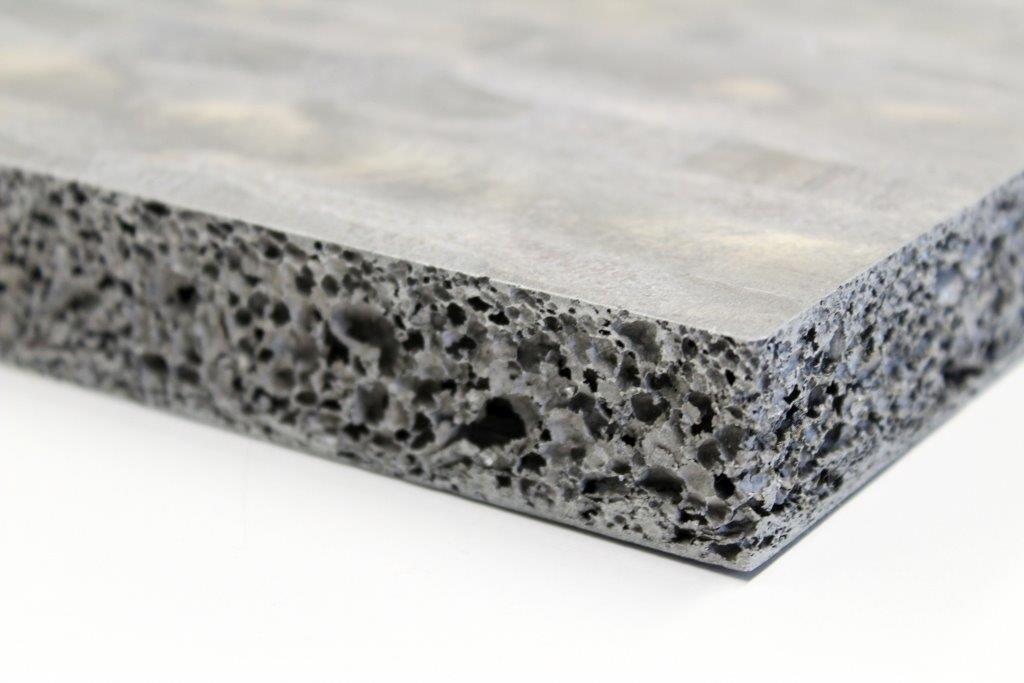

Geschlossenzelliger Aluminiumschaum (schmelzmetallurgisches Verfahren)

Fraunhofer IWU, Abteilung Leichtbau, Textiltechnologien und Circular Economy

category zellularer Werkstofftensile strength 1 – 1.8 MPatensile strain at break – -

Offenzelliger Aluminiumschaum (schmelzmetallurgisches Verfahren)

Fraunhofer IWU, Abteilung Leichtbau, Textiltechnologien und Circular Economy

category zellularer Werkstofftensile strength 1.9 – 3.5 MPatensile strain at break – -

Rhenolub® MK I (GR) (einem organischen Bindeharz mit Molybdändisulfid und Graphit)

Rhenotherm Kunststoffbeschichtungs GmbH

category Kunststoffbeschichtungtensile strength –tensile strain at break – -

category plasticstensile strength –tensile strain at break 250 %

-

category plasticstensile strength –tensile strain at break 300 %

-

category plasticstensile strength 12 MPatensile strain at break 40 %

-

category thermoplasticstensile strength 140 MPatensile strain at break > 150 %

-

category Thermoplastic Compoundtensile strength 100 MPatensile strain at break > 100 %

-

category thermoplasticstensile strength 120 MPatensile strain at break > 150 %

-

category thermoplasticstensile strength 130 MPatensile strain at break > 200 %

-

category Thermoplastic Compoundtensile strength 100 MPatensile strain at break > 150 %

-

category Kupfertensile strength 280 – 1200 MPatensile strain at break > 2 %

-

category Kupfertensile strength 245 – 1200 MPatensile strain at break > 2 %

-

category Kupfertensile strength 140 – 420 MPatensile strain at break > 2 %

-

category Kupfertensile strength 140 – 698.2 MPatensile strain at break > 2 %

-

category cast steeltensile strength 720 – 1130 MPatensile strain at break > 10 %

-

category cast irontensile strength > 180 MPatensile strain at break –

-

category Nickeltensile strength > 1000 MPatensile strain at break > 15 %